As part of my curriculum in MIT’s Advanced Manufacturing and Design Master’s program, I enrolled in 2.830 Manufacturing Process Control. This course teaches the statistical underpinnings of production manufacturing such as process capability, Cpk, experimental design, and much more.

One of my favorite topics of the class was the use of factorial experimental design to create linear models that can predict the contributions of different inputs to a process. By following some very clever experimental structures, one can greatly reduce the number of trials needed to test the effects of different input values on an output of interest.

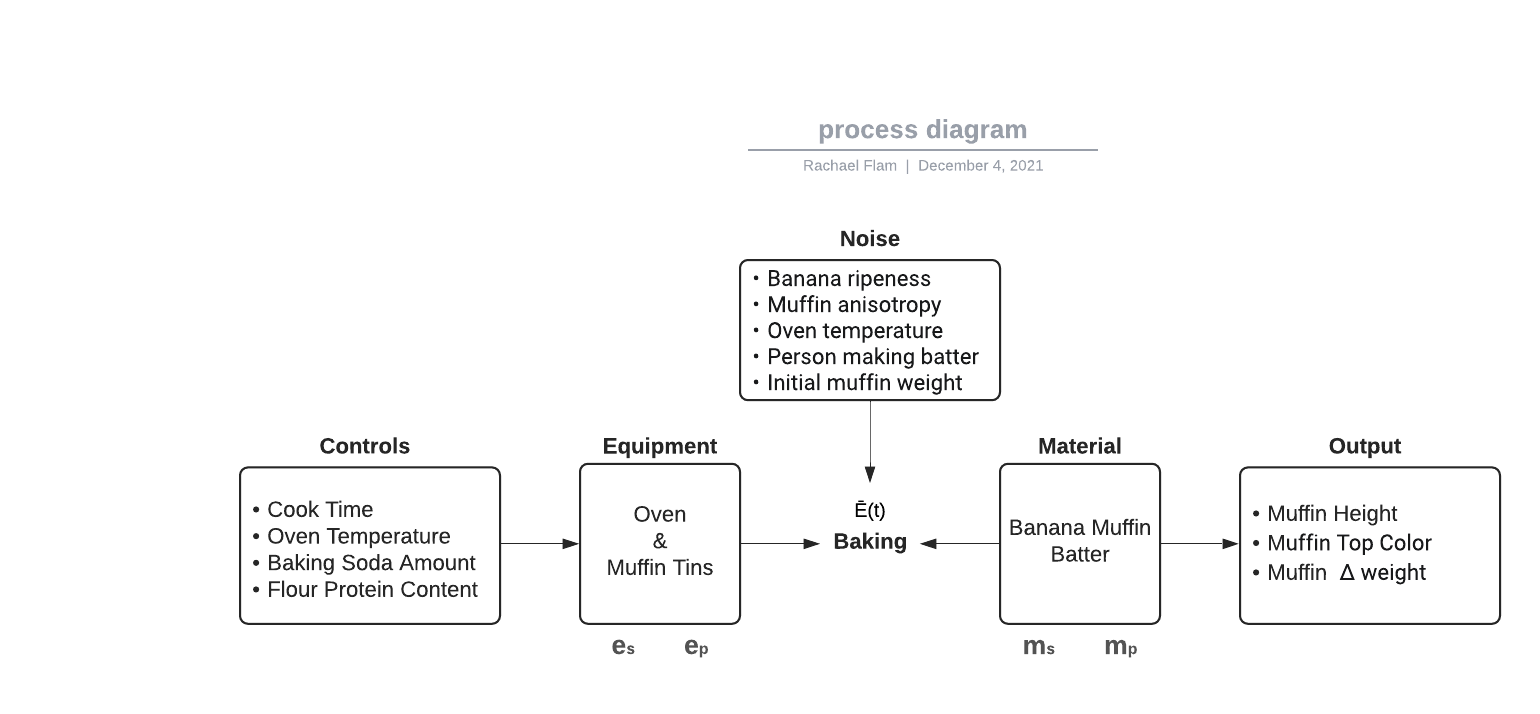

I was eager to apply experimental design as the course’s final project with some friends. We just needed a certain “recipe” to apply our experimental design to. Some sort of process that involves multiple inputs that may interact and can result in a desired outcome.

Well, why not a real recipe?

As we walked past the Banana Lounge, it all became clear. We should optimize the “manufacturing” process of baking banana muffins.

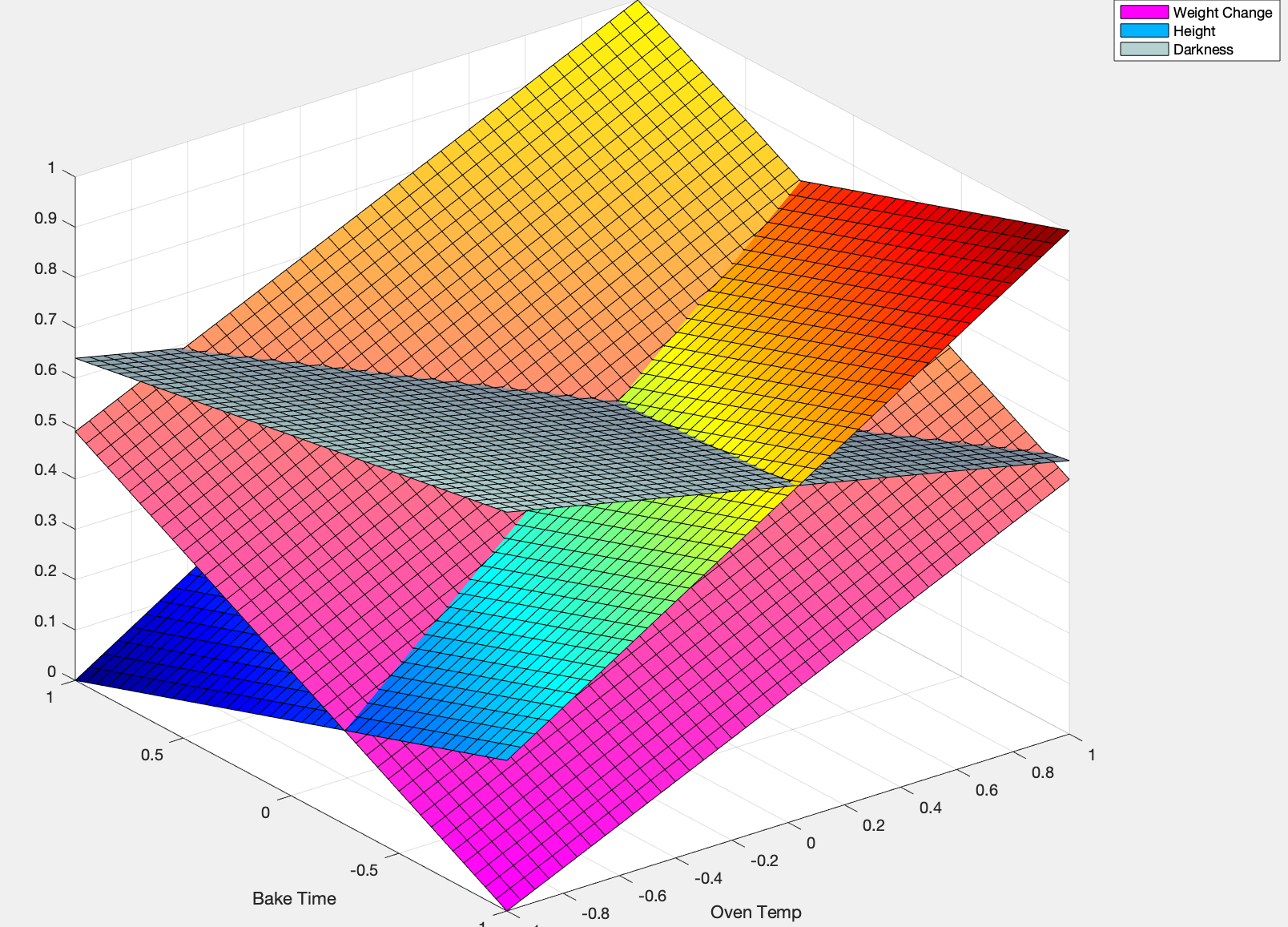

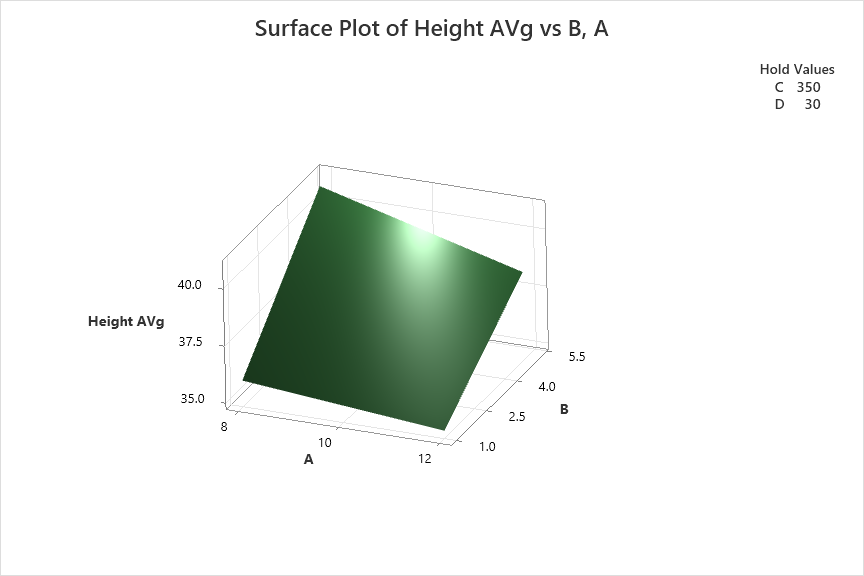

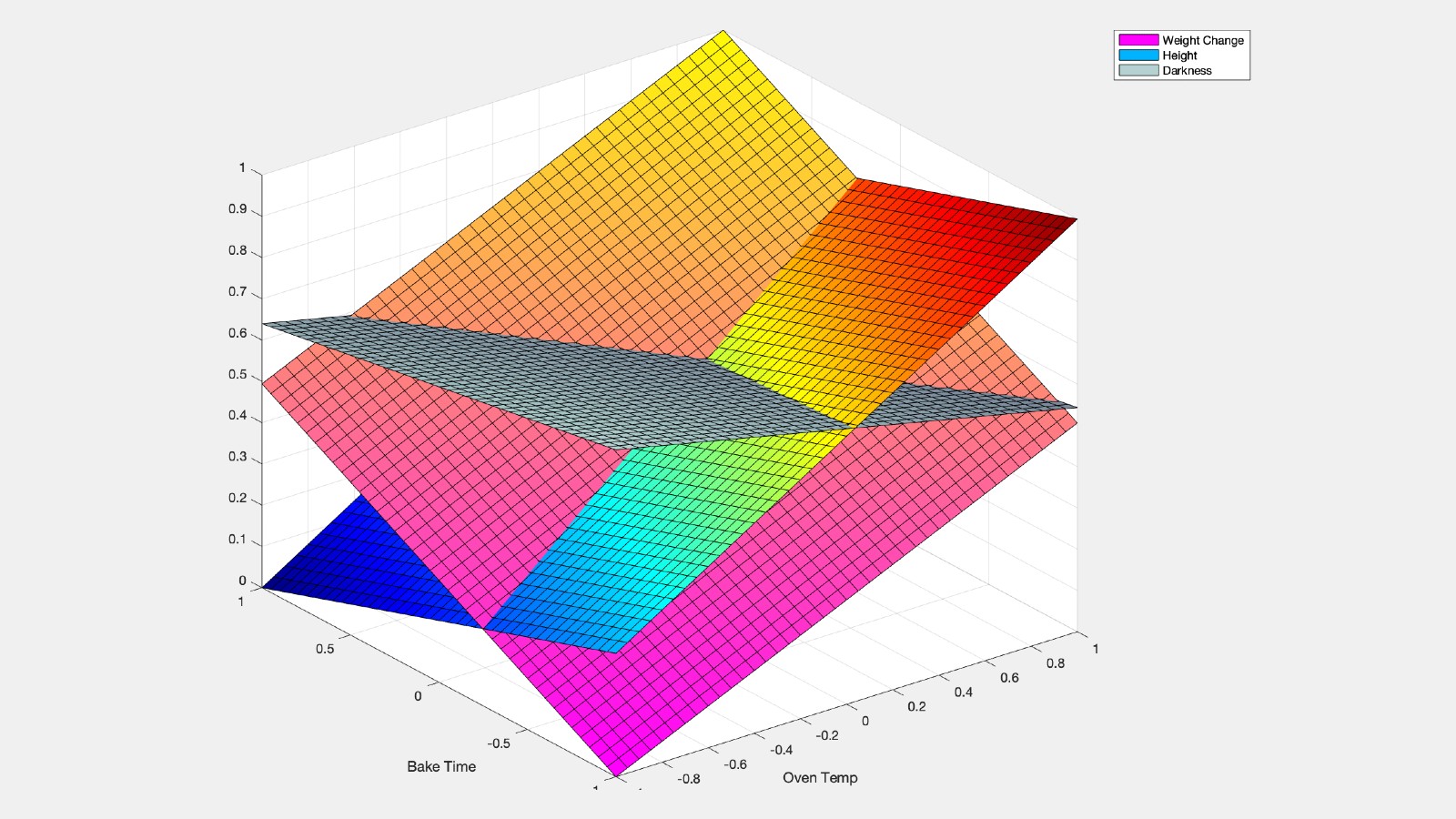

My team and I decided to vary the process inputs of baking time, temperature, flour type, and amount of baking soda added. These were varied in search for the “perfect” banana muffin, which we determined by least change in weight (moister), largest height (least dense), and closest in color to a preselected color value.

We ran a 2^(4-1) experimental design with center points to build linear models for each output, and test for quadratic error. None of the quadratic error terms were significant, so reduced linear models are used for each of the three outputs. The most significant factors across all the models were oven temperature and cooking time. An optimized recipe and baking process were determined by prioritizing these factors and the process output of maximum height.

This optimized banana muffin used 8% flour protein content, 5 grams of baking powder, an oven temp of 357℉, and baking time of 26 minutes. The optimized run of four replicates had a 10.12% error from the height model, 6.08% error for weight, and 3.54% error for color. Overall, the muffins were tall, golden, and moist: reflective of the ideal muffin.