During an internship at an aerospace manufacturing company, I became friendly with the master welder who would fabricate some of the safety critical, tight tolerance components used in turbine engines. He took some time to give me a very quick crash course into TIG welding and I was hooked.

I got an Everlast TIG DC welder in 2019 and have slowly been learning how to TIG weld. I was very quickly humbled by the complexity, coordination, and awareness needed to produce quality work and I have a deep respect for that trade. Fortunately, I am not a welder, so I can get away with work that is not as pretty (nor safety critical!)

Here are a few projects I’ve worked on. All mild steel for now.

I built a crate/cart for my welder that cradles the argon tank at an angle so it can fit under my workbench.

I also made a can crusher for a Secret Santa gift. It consists of a steel platform on a tubular frame with a cheap linear actuator to crush the can.

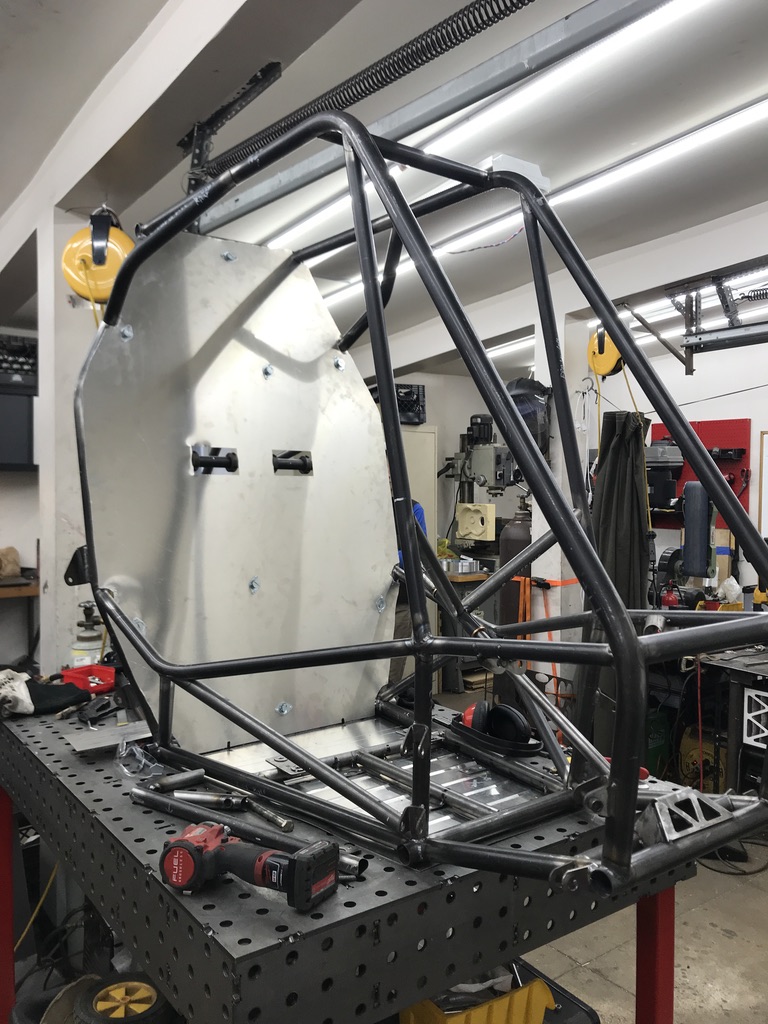

During my time at Stevens, I was part of the SAE Baja team and would occasionally help with fabricating the frame of the car.